Success story: “Heemskerk Fresh and Easy”

Optimize your production process with a Boix Tray Forming machine

“Reliability, that has been one of the main reasons for choosing a Boix machine” (Heemskerk Fresh & Easy)

Heemskerk Fresh & Easy is one of our customers where it started with only one machine, but now has expanded to nine Boix machines!

In 1960 Wim Heemskerk laid the foundation for Heemskerk with the production and sale of bags of sliced soup vegetables on the wholesale market (known as: Groothandelsmarkt) in Amsterdam. In 60 years, Heemskerk fresh & easy has grown into a modern and progressive company that processes fruit and vegetables with innovative products and concepts. They supply around 3.5 million fresh convenience products to retail companies and fast-food chains both at home and abroad every week.

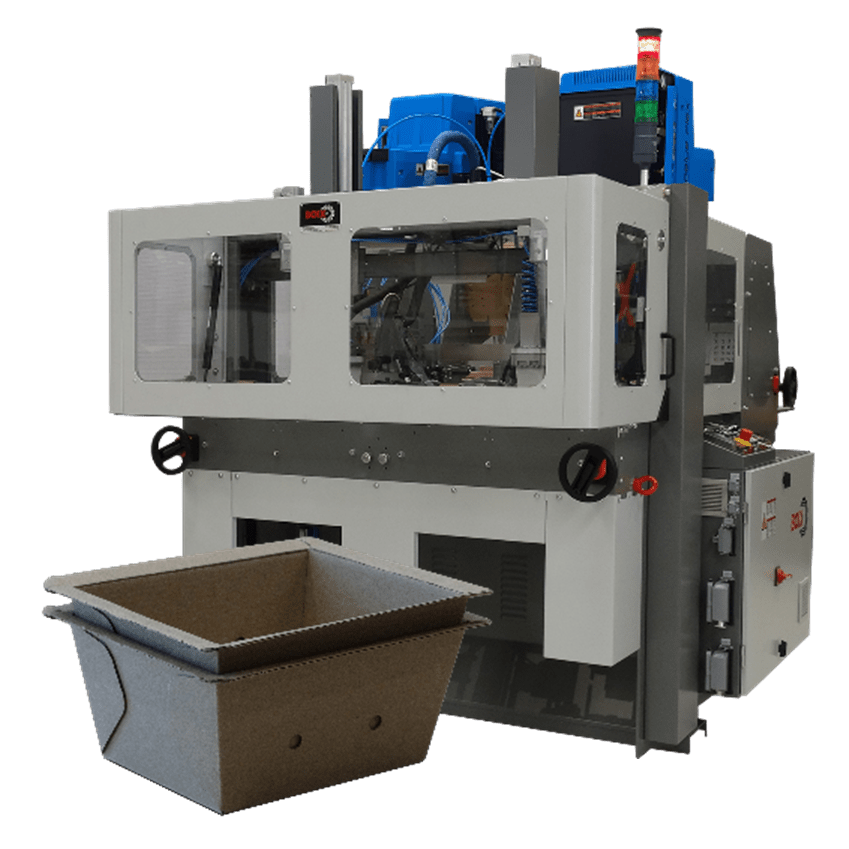

Back in the days Heemskerk was working together with a tray erecting center. This center took care of gluing and forming cardboard trays. After they were formed, the trays were stacked and prepared for transport. As the years went by both demands and production increased. For Heemskerk, this was the right time to invest in their own Boix machines. This made the demand for their own products increase even more. After consultation with Boix Europe eventually a complete machine production line was implemented e.g Boix Pre-Feeders and stackers to automize the manufacturing process.

The pre-feeders can be placed behind or next to the machine which create an extra buffer of around 1000 blanks (BE flute) and automatically fills the existing feeder of the machine. This eventually will lead to savings on labor costs.

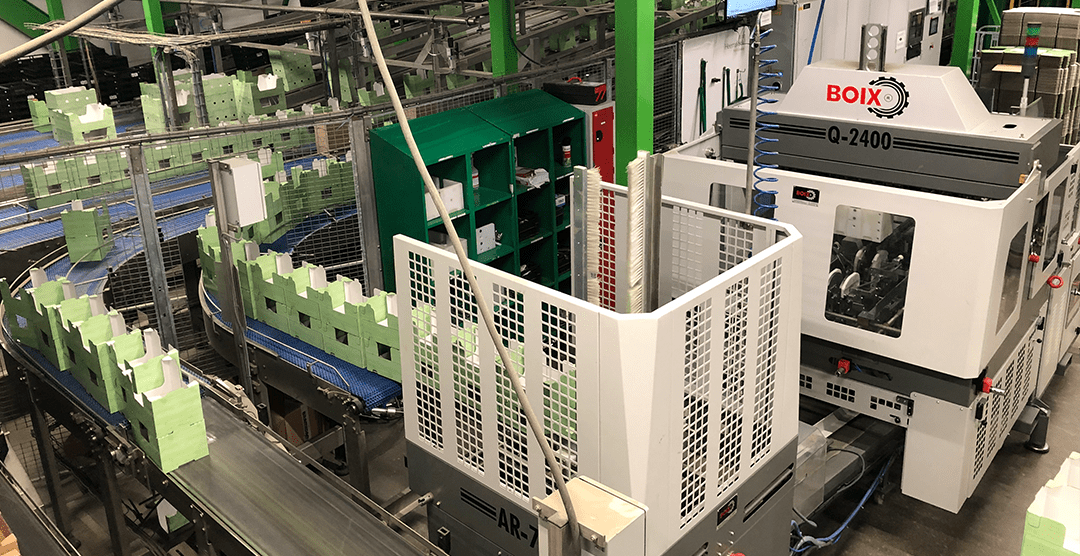

From the central point in Heemskerks factory hall, the Boix Machinery are at the beginning of the boxes and crate transport system. The trays are formed, glued and transferred to the 30 production lines by means of the Boix machines and the Boix accessories.

Sustainability

“Not only are we trying to keep up with the developments of the market and customers, but also with the increasing demands of sustainability. One of our latest machines, the MCT-1/TS, is especially designed for forming and gluing Top Seal punnets. Which can be the solution for sustainable packaging” says managing director of Boix Europe Job Schmidt.

“With our machines there are many possibilities. Whether you have a specific project in mind or if you need more help with finding the right packaging solution for your product, we are here to help.”

The Boix MCT series are also being used as an inline solution by using 2 conveyor belts and erect the punnets one by one to completely automize your packaging line! The end customers can save on labor, logistics and investments cost (for not needing an extra De-nester) by using this solution.

Boix is your forming partner and always open to discuss the possibilities for your company.

Are you looking for sustainable packaging solutions or are you looking for a way to optimize your production process? Find the solution together with Boix!

This post is also available in:

Español (Spanish)

Español (Spanish)